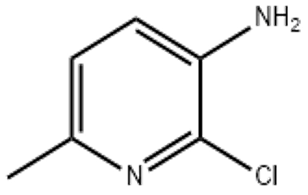

3-amino-2-chloro-6-picoline (CAS# 39745-40-9)

Ubungozi Nokuphepha

| Izimpawu Eziyingozi | I-Xn - Iyingozi |

| Amakhodi Engozi | R36/37/38 – Ukucasula amehlo, uhlelo lokuphefumula kanye nesikhumba. R20/21/22 – Kuyingozi ngokuhogela umoya, ukuthintana nesikhumba futhi uma ukugwinyile. R41 – Ingozi yokulimala okubi emehlweni R37/38 – Ukucasula uhlelo lokuphefumula kanye nesikhumba. I-R22 – Iyingozi uma igwinywe |

| Incazelo Yokuphepha | S36/37/39 – Gqoka izingubo zokuzivikela ezifanele, amagilavu kanye nokuvikela iso/ubuso. S26 – Uma uthintana namehlo, geza ngokushesha ngamanzi amaningi futhi ufune iseluleko sezokwelapha. S39 – Gqoka ukuvikela iso / ubuso. |

| Ama-ID e-UN | 2811 |

| Ikhodi ye-HS | 29339900 |

| I-Hazard Class | 6.1 |

3-amino-2-chloro-6-piccoline (CAS#39745-40-9) Isingeniso

Inhlanganisela iyikristalu eqinile emhlophe enephunga elihlukile. Ingancibilika emanzini kanye nezincibilikisi eziningi eziphilayo. Inhlanganisela izinzile ekushiseni okuvamile, kodwa ingase ibole ngaphansi kwezinga lokushisa eliphezulu noma ukukhanya.

I-5-Amino-6-chloro-2-picoline inezinhlobonhlobo zokusetshenziswa kwezokwelapha namakhemikhali. Isetshenziswa njengengxenye ephakathi ku-organic synthesis futhi ingasetshenziswa ukulungisa izinhlanganisela ezihlukahlukene ze-organic. Ngaphezu kwalokho, ibuye isetshenziswe njengezinto zokusetshenziswa kanye neziphakathi emkhakheni wezibulala-zinambuzane kanye nemithi.

I-5-Amino-6-chloro-2-picoline ingalungiswa ngokusabela kwamakhemikhali kwe-2-chloro-6-methylpyridine ne-ammonia. Ngokuqondile, i-2-chloro-6-methylpyridine negesi ye-ammonia ingasabela ngaphansi kwezimo ezifanele zokusabela, bese ihlanzwa nge-crystallization ukuze kutholwe umkhiqizo ohlosiwe.

Mayelana nolwazi lokuphepha, i-5-Amino-6-chloro-2-picoline iyinhlanganisela yemvelo enezinga elithile lengozi. Kungase kubangele ukucasuka ohlelweni lokuphefumula, isikhumba namehlo. Izinyathelo zokuzivikela ezifanele, njengezibuko, amagilavu nezingubo zokuzivikela ezifanele, kufanele zithathwe lapho kusetshenziswa noma kuhlangana nenhlanganisela. Lapho uphatha lesi sithako, gwema ukuphefumula umhwamuko noma uthuli lwawo futhi uqinisekise ukungena komoya okuhle endaweni yokusebenza. Ekugcinweni nasekulahlweni kwenhlanganisela, izinqubo zokuphepha ezifanele kufanele zilandelwe.

![6-Bromo-7-chloro-3H-imidazo[4 5-b]pyridine(CAS# 83472-62-2)](https://cdn.globalso.com/xinchem/6Bromo7chloro3Himidazo45bpyridine.png)